We are market forerunners

We are a corporation-independent, medium-sized company from Frankfurt am Main specializing in the construction of special systems as well as the development and production of control systems and other electronic components. One of our strengths is our great vertical range of manufacture. Since we manufacture all essential steel construction elements such as cabins, frames, shaft doors and shaft equipment in our own metalworking shop, we are largely independent of the supplier market and can meet many customer requirements beyond the usual dimensions and standards.

Our history

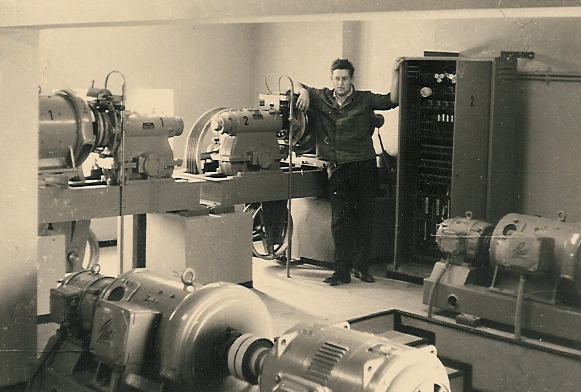

On April 1, 1967, Alfred Thoma, a trained electrician and elevator installer, founded Thoma Aufzüge in Frankfurt am Main. The Bavarian Swabian had previously built up a successful branch in the Main metropolis for an elevator manufacturer from his hometown of Augsburg within a few years. But now the passionate technician and tinkerer wants to go his own way. Initially, Thoma will focus on the development and production of elevator controls. The components are so good that they are also in demand among the major elevator construction companies. At the same time, the founder signs a cooperation agreement with a southern German elevator manufacturer. He sells, assembles and maintains its systems in the Rhine-Main area. However, these are controlled with Thoma’s electronic components. From the very beginning, they were among the most important components for the newcomer to the industry, which is why the company was renamed Electronic Lift Thoma (ELT) in 1979.

On the road to success with quality and flexible solutions

Within ten years, the specialized small business grows into a company that can hold its own against the “big players” in the industry with quality, flexible production and innovative technical solutions. Due to the good order situation, Thoma decides to buy the property Schönberger Weg 6 in Frankfurt and to build a modern production hall with a small office wing there. In 1980, the new location is ready for occupancy. The capacities now make it possible to build up to 100 elevator systems per year. Electronic Lift Thoma is now a medium-sized company that has occupied its market niche as a “noble forge” of high-quality and individually designed elevators from its own production.

Six elevators — one control system

In 1984, a major order from the Hochtief construction group for twelve elevator systems in the so-called Poseidon building at the Frankfurt Trade Fair was groundbreaking. A special challenge: Six of the systems, each with 19 stops, are to be operated via a central group control system. Thoma is the only supplier who has the confidence to do this. Since such an electronic component (a group control for six elevator systems) does not yet exist on the market, the technical know-how of the company’s founder is once again in demand, and he develops and builds the required control system himself without further ado. This control system functioned without any noteworthy problems for over 25 years and was only replaced by a destination selection control system during a revitalization of the entire building.

At the end of the 1980s, a generation change became apparent: After studying electrical engineering, Alfred Thomas’ eldest son Benedikt joined the company in 1987 and took over the management of the Service & Maintenance division. His two younger brothers follow him: Jan Thoma begins his activities in 1988 in the assembly department and learns all the work at the base. Nikolai Thoma also joins the company two years later and initially becomes responsible for the electrical division.

Thoma provides innovative impetus

Gleic

The tasks of the company founder are successively passed on to the next generation: Jan Thoma takes over the management of sales, production and assembly and Nikolai Thoma is additionally responsible for organization and finances.

Again and again, Thoma Aufzüge provides innovative impulses in elevator construction and sets technical standards: In 1989, the company develops its first own microprocessor controls, which are soon used. They replace the tried-and-tested relay controls and enable a wide range of new control options. The first frequency controls followed in the early 1990s. Thoma also develops most of the components required for this itself, as the products are not yet available on the market at this time.

At the same time, digitalization progresses: In 1993, the design department in the company’s planning division is completely converted to CAD.

Elevators beyond usual standards

The company continues to grow and consolidates its reputation as a reliable and flexible manufacturer of high-quality and technically sophisticated installations. In 1994, Thoma completes its 1,000th elevator. To drive this development and extend its technical lead, Thoma establishes its own modernization department.

In 1996, the company premises in the Praunheim district of Frankfurt are expanded once again. Here, elevator systems are constantly being developed that the majority of manufacturers cannot offer at a reasonable price: For the Bundesbank, Thoma manufactures an underfloor elevator with a load capacity of 15 tons, a total weight of 56 tons and develops its own rail system for this purpose. A car elevator in which the car is rotated 180° during travel, a machine room-less elevator with a load capacity of 1.6 tons, systems with a travel speed of 3 meters per second — time and again, Thoma developers solve challenging technical tasks.

In 2002, the company founder and main shareholder Alfred Thoma leaves the company management and goes into his well-deserved retirement.

In the Wandelhalle Bad Wildungen, Thoma hands over the first completely round glass elevator with self-supporting glass shaft frame to the state spa of the health resort in 2006.

In the same year, Benedikt Thoma, the oldest of the three Thoma brothers, decides to make a fundamental change in his life. He ends his activities in the management, leaves the company and emigrates to Canada.

The Thoma Lifter — compact solution for private homes

In 2010, the company draws attention with the Thoma Lifter, a platform lift with glazed aluminum shaft frame for indoor and outdoor use. The compact design can be delivered and assembled as a whole and is particularly suitable for equipping private homes with a lift.

In 2012, Electronic Lift Thoma is renamed back to the traditional Thoma Aufzüge brand. The renaming simplifies marketing (family name and product) and enables a unified name with the new business segment Thoma Lifter.

The fastest installations for Thoma were realized in 2013: a group of three with fireman’s elevator and destination selection control and a travel speed of 4.0 m/s.

Once again, the company has to expand its capacities: the production had become too small, the machinery obsolete and the warehouse no longer reasonable to organize. After the new construction and remodeling, which had already begun in 2012, around 4500 square meters will be available for production, warehouse and office as of May 2014.

Components — Thoma quality from the Online Shop

The requests for components and spare parts are increasing, which is why Thoma decides to reorganize this area. In 2017, the new Thoma Components homepage goes online.

Unfortunately, not everything always runs smoothly at Thoma either:

Over the years, there are repeated disagreements between the remaining shareholders Nikolai and Jan Thoma. Discussions focus on their personal future and the development of the company. The long-standing quarrels end with Nikolai Thoma leaving the management and as a shareholder at the end of 2019. From then on, Jan Thoma will continue the straightforward, high quality-oriented course of the company founder Alfred Thoma. This will ensure the continued existence of the company, including jobs.

Leadership team

All experts have more then 20 years

experience in engineering and building elevators

our founder

Alfred Thoma

A high quality standard, our own flexible production and great know-how in the construction of special systems and individually designed elevators are our essential trademarks. The continuous striving for improvements and optimal solutions, you could also call it inventiveness, are also part of the Thoma “DNA”. They are the legacy of the company’s founder, Alfred Thoma, a man who was an ingenious tinkerer, inventor, tireless entrepreneur and vigorous hard worker all at the same time, a patriarch in the most positive sense.

Older employees who experienced him as a boss still speak with a certain reverence of the “old man,” whom some locksmiths and fitters sometimes called “Chief Silver Curl” or “White Shark” behind closed doors, in allusion to his prematurely graying, wispy hair, but also because they respected him as their “leader. Both of these attributes suited the powerful appearance of this straightforward, energetic entrepreneurial personality, a man for whom diligence, reliability and honesty were non-negotiable virtues.

read more

From elevator fitter to respected entrepreneur

Without these qualities, Alfred Thoma would probably not have followed such an unusual and impressive career path. It led the “boy from Bavarian Swabia”, who had herded cows barefoot in his childhood, via an apprenticeship as an electrician and elevator fitter, finally to a successful and respected elevator manufacturer, who held his own against the big players in the industry time and again with tenacity and an ingenious understanding of technology.

In 1953, Thoma completed his apprenticeship at the Kammgarnspinnerei in Augsburg. As an electrician, he maintained elevator systems there and began to become enthusiastic about this technology. He

decides to join Bauer Aufzüge — another Augsburg company — and learns how to manufacture and install complete elevator systems from scratch.

Because of his good work, Thoma is sent to Frankfurt with the assignment of setting up a branch office there for the company. He has only his toolbox in his luggage when he arrives in the city. Bauer, he hands over a branch office with 30 employees in 1967.

With willpower and inventiveness

After some minor friction, Alfred Thoma parts ways with the company and decides to go into business for himself. Initially, he mainly manufactures control components and signs a cooperation agreement with another southern German elevator manufacturer. Thoma sells the latter’s systems in the Rhine-Main region and installs and maintains the elevators. From the very beginning, however, they are equipped with his own products — control systems from his company Thoma Aufzüge.

The firm belief in doing things better, achieving goals with willpower and inventiveness, and the urge to “show others how it’s done” have always been important driving forces for Alfred Thoma. As early as 1969, in the company’s second year, he and a handful of men assembled a system with 14 stops at Bad Homburg’s Untertor. In the same year, the industry newcomer completes 14 installations. At that time, Thoma Aufzüge was still basically a three-man operation, supplemented by a few assistants, in which Thomas’ older sons also worked a few years later.

His first employees were a sworn troop. For anyone who wanted to work for Thoma, the willingness to work hard for good money was the ticket. “I went three times to apply,” says Horst Zschenderlein, who ultimately worked for Thoma for more than 50 years and is considered one of the “veterans” in the company. “At the first interview, they said I was too weak.” But in the end, “the old man” recognized his will to work, “and will was all that mattered.”

Motivator, driver — and fair employer

In the first few years, the boss himself lent a hand, accompanied all transports and also helped with unloading and assembly. Even injuries did not stop him from working, reports Zschenderlein.

Thoma was always a motivator and driver and always set a good example. If someone in his team objected, he countered in his own way. His motto: “If you don’t want to do it, I’ll do it myself.” Alfred Thoma was incorruptible in every respect. Sometimes the boss pushed his people until he himself was exhausted. Overtime was normal, especially when a deadline for the completion of a plant was approaching.

At the same time, he was always generous and fair when he was satisfied with the performance of his team, sometimes in an unconventional way. He let employees use a company car for family vacations, handed out cash bonuses after a decent performance, bought rounds of pizza and beer, or spontaneously increased the hourly wage by a few pennies when someone fetched a cold beer for him. Because when it came to his favorite drink, he was and remained a Bavarian: Thoma, who had chosen to live in Frankfurt, also enjoyed a wheat beer at lunchtime.

Thomas technical skills convince

But it was not only the fairness and physical presence of the hands-on tinkerer that secured him the loyalty of his workforce. Thoma also won over the workforce with his technical skills. “He was dynamic and determined,” one former employee describes him. “And we always had the feeling that what he put his hand to, he could do.”

At that time, the loyalty of the employees went so far that one of them once privately lent the entrepreneur a large sum of money when the house banks did not want to grant an important loan despite a good order situation. Sure, those were different times, but the example shows the team spirit that shaped Thoma’s corporate culture and still does today.

With its technical developments — especially the innovative control systems — Alfred Thoma surprised its customers and competitors time and again. They enabled fast but at the same time very comfortable elevator rides. In 1978, he presented his innovative controls at the Hanover Fair and subsequently sold them in large quantities. Thoma expanded his company in Frankfurt during this period and from 1980 onwards manufactured more than 80 elevator systems per year.

An ingenious tinkerer who is trusted by customers

Thoma develops microprocessor controls, machine room-less elevators, new designs for heavy-duty elevators and uses gearless drives for high travel speeds at an early stage. The fact that Thoma Aufzüge has established itself over many years as a specialist for particularly demanding installations is primarily due to the inventive spirit of the company’s founder Alfred Thoma, his passion for mastering technical challenges and searching for optimal solutions.

Of particular importance in 1986 was the supply and installation of twelve elevator systems in the “Poseidon-Haus”, a high-rise office building on Theodor-Heuss-Allee opposite the trade fair in Frankfurt. There, Alfred Thoma realized, among other things, a group of six elevators with 19 landings and a travel speed of 2.0 m/s, which were in operation for more than 25 years by means of relay control.

Without knowing it in advance, Thoma once again performed pioneering work.

Up to that time, there was no company in Germany that could centrally control a group of six elevators.

control of a group of six elevators.

The resourceful elevator manufacturer only really realized what he had achieved when the elevators were accepted and handed over. The responsible employees of the client, Hochtief, expressly thanked and praised Thoma, saying: “We knew you could do it!”

Honesty, commitment and transparency

This trust of regular customers, especially Hochtief and Philipp Holzmann AG, led to Hochtief ordering 30 high-performance systems for a high-rise building from Thoma in the early 1990s. The order was admittedly too large for his company’s capacities. But the experienced businessman quickly joined forces with a competitor who was keen to “get on board”, and the two companies handled the order together.

For a long time now, Thoma Aufzüge has had its own department working on technical development.

Alfred Thoma’s youngest son Jan, who now runs the company, adheres to his father’s system of values and principles, and thus successfully holds his own in an increasingly tough competitive environment in which the only thing that often matters is cutting costs.

An honest, binding and transparent relationship with customers, reliability,

quality and a spirit of innovation are the legacy of Alfred Thomas, which will continue to guide Thoma Aufzüge in the future.